Call for Emergecy

+961 3 638901

In recent years, manufacturers of condensing units have more and more gone to motor-compressor units and direct-drive

compressors, which means that the compressors are turning at motor speeds. These relatively high-speed compressors

cannot operate without proper lubrication at all times. Even more than formerly, adequate oil return must be maintained.

Proper piping is conducive to long life and minimum repairs to the equipment, such as reduction of damage to compressors

by broken valves, burned out bearings and scored cylinders by the lack of proper oil return; and damage to expansion valves

due to wire drawing as a result of flash gases, to name only a few of the possible damages. After all, it is to the best interest

of all to make the customer’s equipment operate as efficiently and economically as possible.

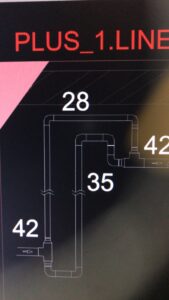

locations decide the design of the piping as well as the size and length, and they also determine the necessary valves and

fittings. The first thing to do then is to make a layout. For small installations, the layout may even be mental; but there should

be a thought-out plan before is started